Flange Guards UK Safety Spray Shields Solutions

SUREBAND Clear

All-PTFE. Outlasts conventional PTFE- COATED fibreglass shields in corrosive environments.

SUREBAND Steel

All-316 ST/ST banding and mesh. Suitable for high pressure and temperature applications.

SUREBAND Marine

Specifically for marine engine room solas applications.

SAFER

Our PDT technology makes Sureband THE most cost effective shield design on the market. Be sure, be safe, choose Flangeguards.

QUICKER

No pull-cords. Quick fit connection cuts install time

dramatically, saving time &

money. Operators are more inclined to re-fit after removal.

BETTER

Best-in-class materials of

construction and

performance.

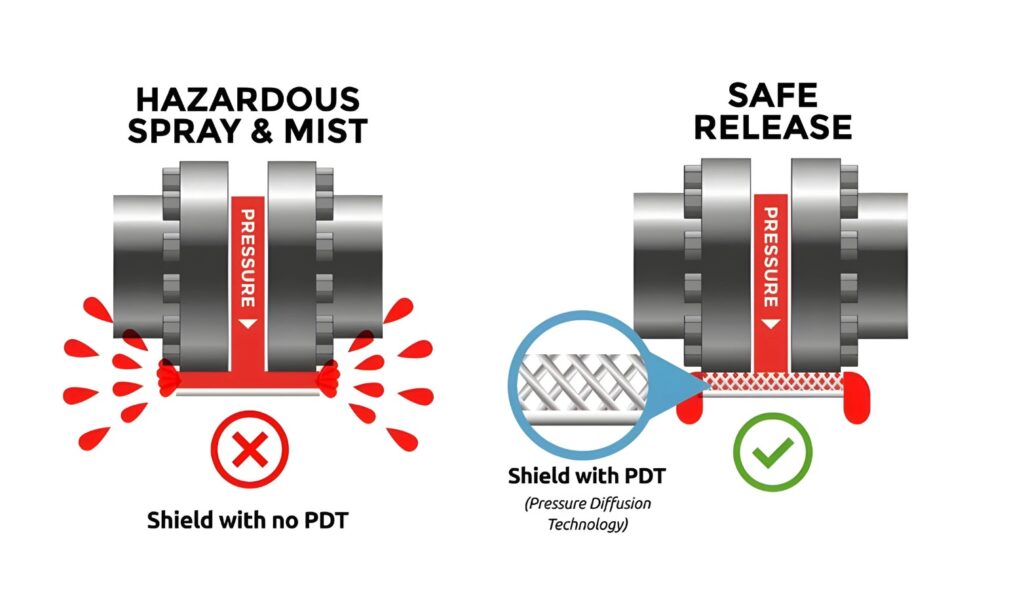

PDT Technology

Pressure Diffusion Technology (PDT)

PDT Mechanism

• PDT (Pressure Diffusion Technology) uses a specially formulated multi-layered mesh that is held against the flange.

• The pressure is diffused in a controlled manor thus preventing formation of a mist/vapour cloud.

• At the point of exit from the shield, the leak takes the form of a safe, vertical drip or stream.

• Our leak testing facility has proven that pressure diffusion is required to prevent spray and mist formation.

• However, many shield designs have no diffusion – and this can actually create a worse leak than no shield at all.

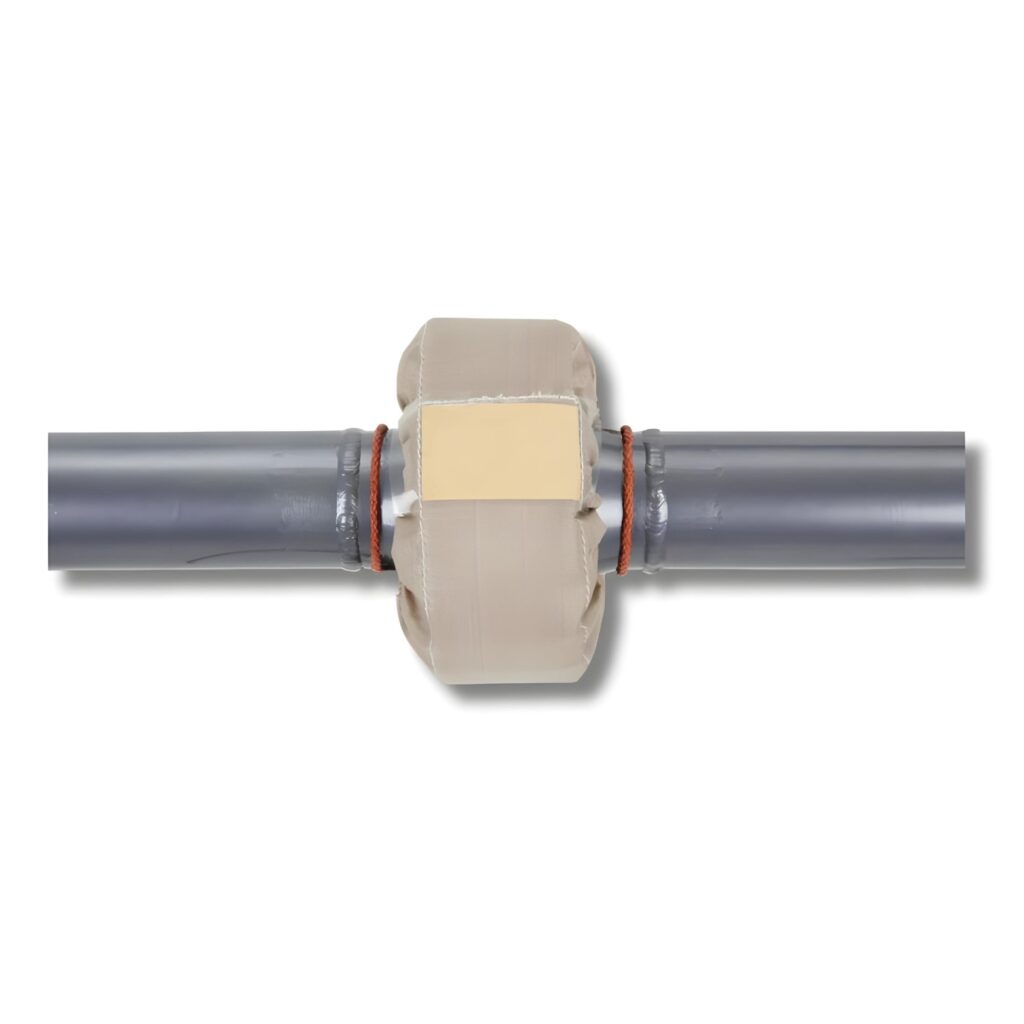

FABRIC Safety Shields

Introduction to FABRIC Safety Shields

• The original wrap-round safety shield design, used extensively throughout industry.

Purpose of Safety Shields

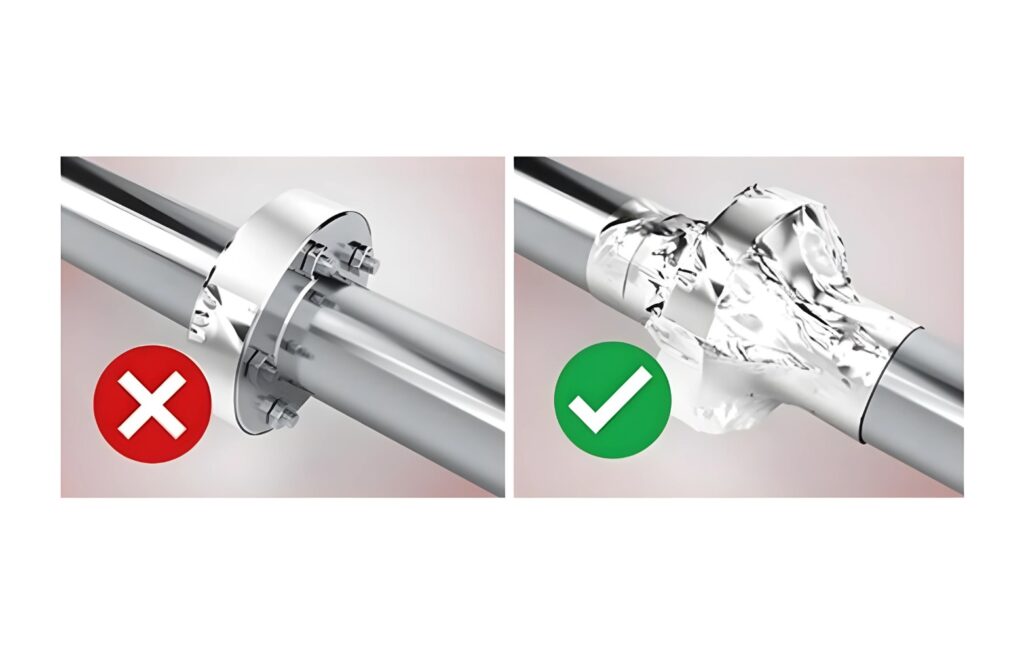

• Safety Shields are fitted to pipe joints to stop:

• Spray-Out / Splashing

• Mist Formation

Typical Applications of Safety Shields

• Oil (Fuel, Lube, Thermal, Hydraulic)

• Acid

• Caustic

• High Pressure Steam

FABRIC Safety Shields

Two-layer PVC shield, offered as a

low-cost alternative, where process

conditions allow. Typically used for

low corrosion applications for

ambient pressure and temperature

conditions.

Two-layer PVC shield, offered as a

low-cost alternative, where process

conditions allow. Typically used for

low corrosion applications for

ambient pressure and temperature

conditions.

Like the PTFE shield, offered as a

low-cost alternative, where process

conditions allow.

Typically used for low corrosion

applications for ambient pressure

and temperature conditions.

Introduction to FABRIC Safety Shields

• The original wrap-round safety shield design, used extensively throughout industry.

Purpose of Safety Shields

• Safety Shields are fitted to pipe joints to stop:

• Spray-Out / Splashing

• Mist Formation

Typical Applications of Safety Shields

• Oil (Fuel, Lube, Thermal, Hydraulic)

• Acid

• Caustic

• High Pressure Steam

SUREBAND Marine

Introduction

• SUREBAND Marine is a simple and cost-effective solution.

Overcoming Issues

• Overcoming issues relating to conventional ANTI-SPLASH tape.

Flexibility

• With 3 shields covering 139 flange sizes, SUREBAND Marine offers unparalleled flexibility.

Additional Option

• Additionally, we offer a 10m roll which can be cut and used to fit virtually any flange (standard or non-standard).

Cost comparison between SUREBAND Marine and ANTI-SPLASH tape

ANTI-SPLASH Tape

• ANTI-SPLASH Tape is a single-use product, which must be peeled or cut off during maintance, with new tape applied afterwards.

• Over the vessel lifetime, this becomes increasingly expensive, sourcing new tape from ship chandlers.

Cost per flange

• Cost per flange depends on several factors.

• Most important is the way the tape is installed.

• Manufacturer’s instructions specify that flanges are wrapped down to the pipe.

SUREBAND Marine

• SUREBAND Marine is fitted and removed in seconds (no tools).

• This means it can be reused after maintenance, proving a long-term solution.

• Three sizes fit multiple flanges and for ultimate flexibility, a 10 metre roll is available.